How Do Micro Thermoelectric Coolers for Detector Improve Detection Accuracy and Stability?

2026-01-12

In modern sensing and analytical systems, temperature stability is one of the most critical factors influencing detector performance. Even slight temperature fluctuations can introduce noise, drift, or signal distortion, directly reducing measurement accuracy. This is why Micro Thermoelectric Coolers for Detector have become essential components in infrared detectors, photodiodes, CCD/CMOS sensors, gas detectors, and scientific instruments. By providing precise, fast, and reliable temperature control in a compact form factor, micro thermoelectric coolers enable detectors to operate at their optimal performance point under demanding conditions.

What Are Micro Thermoelectric Coolers for Detector?

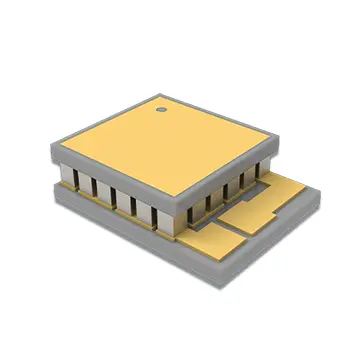

Micro Thermoelectric Coolers for Detector are miniature solid-state devices based on the Peltier effect. When an electric current passes through the thermoelectric elements, heat is actively transferred from one side to the other, allowing precise cooling or heating without moving parts.

Compared with traditional cooling methods, micro thermoelectric coolers offer:

-

Compact size suitable for detector integration

-

Precise temperature control (±0.1°C or better)

-

High reliability and long service life

-

No vibration or noise

Why Are Micro Thermoelectric Coolers Critical for Detectors?

Detectors are highly sensitive to thermal changes. Temperature variations can cause:

-

Increased dark current in photodetectors

-

Reduced signal-to-noise ratio

-

Wavelength drift in optical systems

-

Measurement instability over time

By integrating Micro Thermoelectric Coolers for Detector, manufacturers can maintain a stable detector temperature, significantly improving accuracy, repeatability, and long-term reliability.

Key Functions and Effects of Micro Thermoelectric Coolers

Main Functions

-

Temperature stabilization for sensitive detector elements

-

Noise reduction by minimizing thermal interference

-

Performance optimization under varying ambient conditions

Practical Effects

-

Enhanced detection sensitivity

-

Improved measurement consistency

-

Extended detector lifespan

Micro Thermoelectric Coolers vs. Traditional Cooling Methods

| Aspect | Micro Thermoelectric Coolers | Traditional Cooling |

|---|---|---|

| Size | Ultra-compact | Bulky |

| Control Accuracy | Very high | Limited |

| Moving Parts | None | Yes |

| Noise & Vibration | None | Present |

| Maintenance | Minimal | Higher |

This comparison clearly shows why Micro Thermoelectric Coolers for Detector are preferred in precision and miniaturized detection systems.

Typical Applications

-

Infrared and thermal imaging detectors

-

Optical and laser detection modules

-

Medical and biochemical sensors

-

Industrial gas and environmental detectors

At Fuzhou X-Meritan Technology Co., Ltd., we specialize in designing and manufacturing high-performance micro thermoelectric cooling solutions tailored for advanced detector applications.

Why Choose Fuzhou X-Meritan Technology Co., Ltd.?

-

Proven expertise in thermoelectric technology

-

Custom-designed solutions for detector integration

-

Stable performance, high reliability, and strict quality control

-

Professional technical support and fast response

Our Micro Thermoelectric Coolers for Detector are engineered to meet both technical requirements and commercial goals, helping our partners gain a competitive edge in the market.

Conclusion

As detectors continue to evolve toward higher sensitivity, smaller size, and greater precision, Micro Thermoelectric Coolers for Detector play an increasingly important role. They ensure thermal stability, enhance signal quality, and improve overall system performance. If you are looking for reliable, efficient, and customizable thermoelectric cooling solutions, Fuzhou X-Meritan Technology Co., Ltd. is your trusted partner—contact us today to explore how our products can support your next-generation detector systems.